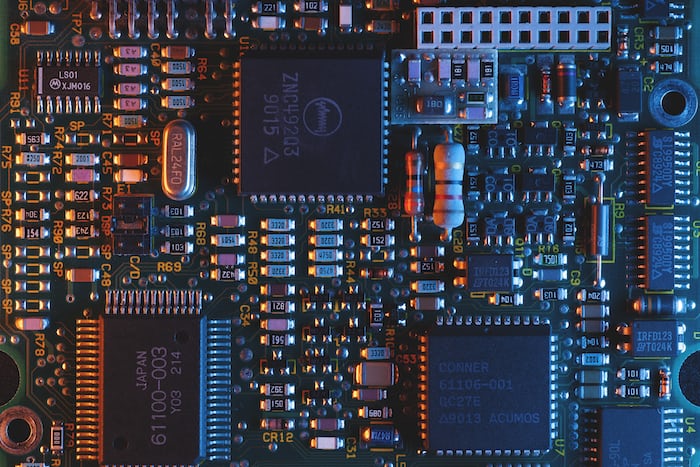

Printed circuit boards (PCBs) are the foundation of electronic gadgets, providing a structure for the coupling of many components. The fire categorization of PCBs, which is critical in ensuring the security and dependability of electrical appliances, is sometimes disregarded. This article will discuss the importance of fire ratings, specifically concentrating on the commonly used 94V0 standard.

What is the PCB fire rating?

A PCB’s capacity to withstand combustion and limit fire spread is indicated by its fire ratings. This characteristic is critical in situations where electronics may be exposed to severe environments and safety is vital. Fire ratings are defined to provide consistency and reliability among PCBs.

The 94V0 Standard:

Among the different fire evaluations; 94V0 is a commonly recognized and used regulation in the electronics sector. The “94” in 94V0 stands for the Underwriters Laboratory (UL) 94 standard, which specifies the criteria to determine the danger of fire risk of plastic elements used in electronics.

After applying the test flame, the specimens cannot burn with fiery combustion for longer than ten seconds. Moreover, For every set of five specimens, the total flaring combustion duration cannot be more than fifty seconds for ten flame applications.

Key Characteristics of 94V0:

Vertical Flame Test:

The 94V0 standard provides a vertical flame test, which involves exposing a vertically positioned PCB specimen to a flame for a set amount of time. The capacity of a substance to consume itself naturally after a set amount of time influences how well it behaves.

Dripping and Afterflame:

The material is also assessed for dripping during the test and the after flame duration. Higher fire ratings are associated with faster self-extinguishing capabilities and less tendency to drip.

Classification Criteria:

The UL 94 standards categorize materials from V-0 to V-2 based on their flame test results. The strictest classification, V-0, denotes the maximum degree of flame retardancy.

Importance of 94V0 in Electronics:

Safety Compliance:

Compliance to the 94V0 standard is frequently an essential for electronic components, particularly in businesses where safety regulations are strictly followed. It makes certain that the PCBs utilized in the gadgets have a great degree of fire resistance.

Market Acceptance:

Goods with PCBs that meet the 94V0 standard are more well-liked by consumers. This is especially important for firms trying to build credibility and confidence with customers and authorities.

Application Diversity:

A large variety of electronic products, including consumer electronics and industrial equipment, can be used with the 94V0 standard. Due to its adaptability, producers in a variety of industries choose it.

Conclusion:

In conclusion, knowing a PCB’s fire rating is essential to guaranteeing the dependability and security of electrical appliances. With its stringent testing requirements, the 94V0 standard offers a trustworthy reference point for assessing the flame-retardant qualities of PCB materials. To comply with safety rules, secure market acceptance, and guarantee the durability of electronic equipment in a variety of applications, manufacturers and designers need to give top priority to adhering to such standards.